HDY22 インパクトパイルハンマー |高い打撃エネルギーと耐久性のある構造

| ハイライト | 水力衝突ハンマー 高衝撃エネルギー,HDY22 パイルハンマー 耐久性のある構造,保証付きの衝撃ピールハンマー |

||

|---|---|---|---|

製品キーワード:油圧インパクト杭打機、インパクト杭打機、杭打機、HDYシリーズ杭打機、基礎建設機械、ヘビーデューティー杭打機。

HDYシリーズ油圧インパクト杭打機は、世界中の要求の厳しいプロジェクト、特に東南アジア、インド、ロシアなどの主要市場向けに設計された、高性能でエネルギー効率の高い基礎ソリューションです。EシリーズおよびDシリーズの発電所とシームレスに統合するように設計されており、多様で困難な土壌条件下で、プレハブコンクリート杭と鋼管杭の打ち込みに強力で信頼性の高い性能を発揮します。

高度な油圧および電気システム:Rexrothメインポンプとバルブ、Parker補助ポンプ、Hedekeろ過システムなどの最高級コンポーネントを組み込み、最適な安定性、効率性、および制御を実現します。

高効率発電所:堅牢なディーゼルエンジン(HDY25のQSZ13など)と、定格動作電流200〜250Aの最適化された油圧回路を備えており、より軽量な120〜150 mm²アルミニウムケーブルを使用して、作業疲労を軽減できます。

優れた冷却と温度管理:高出力トリプルオイルクーラーと精密サーモスタットを装備し、油圧オイル温度を効果的に管理します。これにより、高温環境下でも一貫した性能が保証され、コンポーネントの寿命が延びます。

耐久性のある構造とシーリング:油圧シリンダーには国際グレードのTrelleborgシール、過酷な作業環境での最大の耐久性とダウンタイムの最小化のために強化された機械構造を採用しています。

多用途の互換性:D550発電所は、インパクトハンマーと振動ハンマーの両方と組み合わせることができ、さまざまなプロジェクト要件に対応する柔軟な構成を提供します。

過酷な条件下での実績のある信頼性:ロシアの変動する気候、インドの集中的なプロジェクト、東南アジアの湿潤な環境における建設現場の厳しい要求に耐えるように、プレミアムコンポーネントと堅牢な設計で構築されています。

高い生産性と省エネ:燃料消費量と動作ノイズを抑えながら強力な衝撃エネルギーを提供し、効率的で環境に配慮した建設のニーズに対応します。

運用コストの削減:高精度ろ過によるシステムの清浄度の向上と効果的な熱管理により、故障率が大幅に低下し、サービス間隔が延長され、稼働時間が長くなり、総所有コストが削減されます。

ユーザーフレンドリーな操作:安全性と使いやすさを考慮して設計されており、簡素化された制御と論理的なシステムレイアウトにより、メンテナンスと操作が容易になります。

| モデル | 最大ストライクエネルギー(kN.m) | ストライキングボディ重量(kg) | ストライク周波数(bpm) | 総重量〜(kg) |

|---|---|---|---|---|

| HDY18 | 270 | 18,000 | 20-70 | 27,100 |

| HDY20 | 300 | 20,000 | 20-70 | 32,350 |

| HDY22 | 330 | 22,000 | 20-70 | 34,680 |

| HDY25 | 375 | 25,000 | 20-70 | 38,000 |

ハンマーコアストローク:1500 mm(HDY10以上のモデルの場合)。

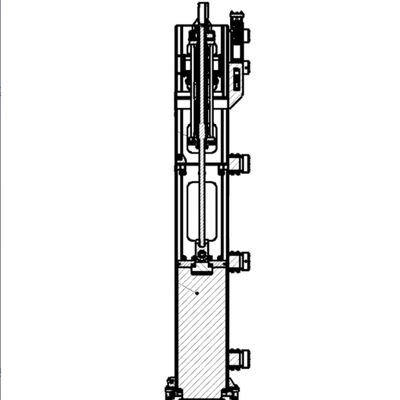

設計:機械式ハンマー本体、油圧動力システム、電気制御ユニットで構成されるモジュール構造。

このシリーズは、港湾、橋梁、高層ビル、工業プラントなどの大規模インフラプロジェクトに最適です。その耐久性とパワーにより、以下の請負業者に好まれています。

東南アジアとインド:通常、高温条件下での沖積土、粘土、砂への杭打ち用。

ロシア:寒冷地での信頼性の高い動作と、さまざまな地質層での安定した性能。

Q1:HDYインパクト杭打機が東南アジアのような高温環境に適しているのはなぜですか?

A:高度な高出力オイルクーラーと精密温度制御システムは、連続運転中の油圧過熱を防ぎ、高温環境下での安定した性能とコンポーネントの保護を目的として特別に設計されています。

Q2:このハンマーは、ロシアの一部など、非常に寒い条件下で動作できますか?

A:はい。高品質の油圧コンポーネントとシールの使用、および適切なグレードの油圧作動油を使用するオプションにより、寒冷地での信頼性の高い起動と動作が保証されます。強制換気設計も、最適なシステム状態の維持に役立ちます。

Q3:インドや遠隔地でのプロジェクトでは、どのようなアフターサービスサポートが利用できますか?

A:主要なOEMへの確立されたサプライヤーとして、プロジェクトの場所に関係なく、詳細なドキュメント、リモート技術支援、スペアパーツ供給のネットワークなど、包括的なサポートを提供し、ダウンタイムを最小限に抑えます。

Q4:エネルギー効率の高い設計は、どのようにコスト削減につながりますか?

A:効率的な油圧システムは、ディーゼル燃料の消費を削減します。さらに、優れたろ過と冷却によるフィルター、シール、および油圧オイルの耐用年数の延長は、機器の寿命全体にわたってメンテナンスと運用コストを直接削減します。

Q5:HDY22またはHDY25モデルには、どのようなキャリアマシンが推奨されますか?

A:これらはヘビーデューティーユニットです。専用の杭打ち機や高容量のクローラークレーン(通常は100トン以上、作業半径によって異なります)などの、大型で安定したキャリアが必要です。それらの重量と動作反力を安全かつ効果的に処理するためです。